swift

Never sharpen your knife again

Kitchen knives should be sharpened 1-2 times per year, and honed after 2-4 uses. Generally, the harder the steel grade, the less often it will need to be sharpened. What if there was a way to never need to sharpen your knife after regular use?

Since the dawn of time, knife design has evolved based on the materials available during that era. Typically, knives get stronger over time.

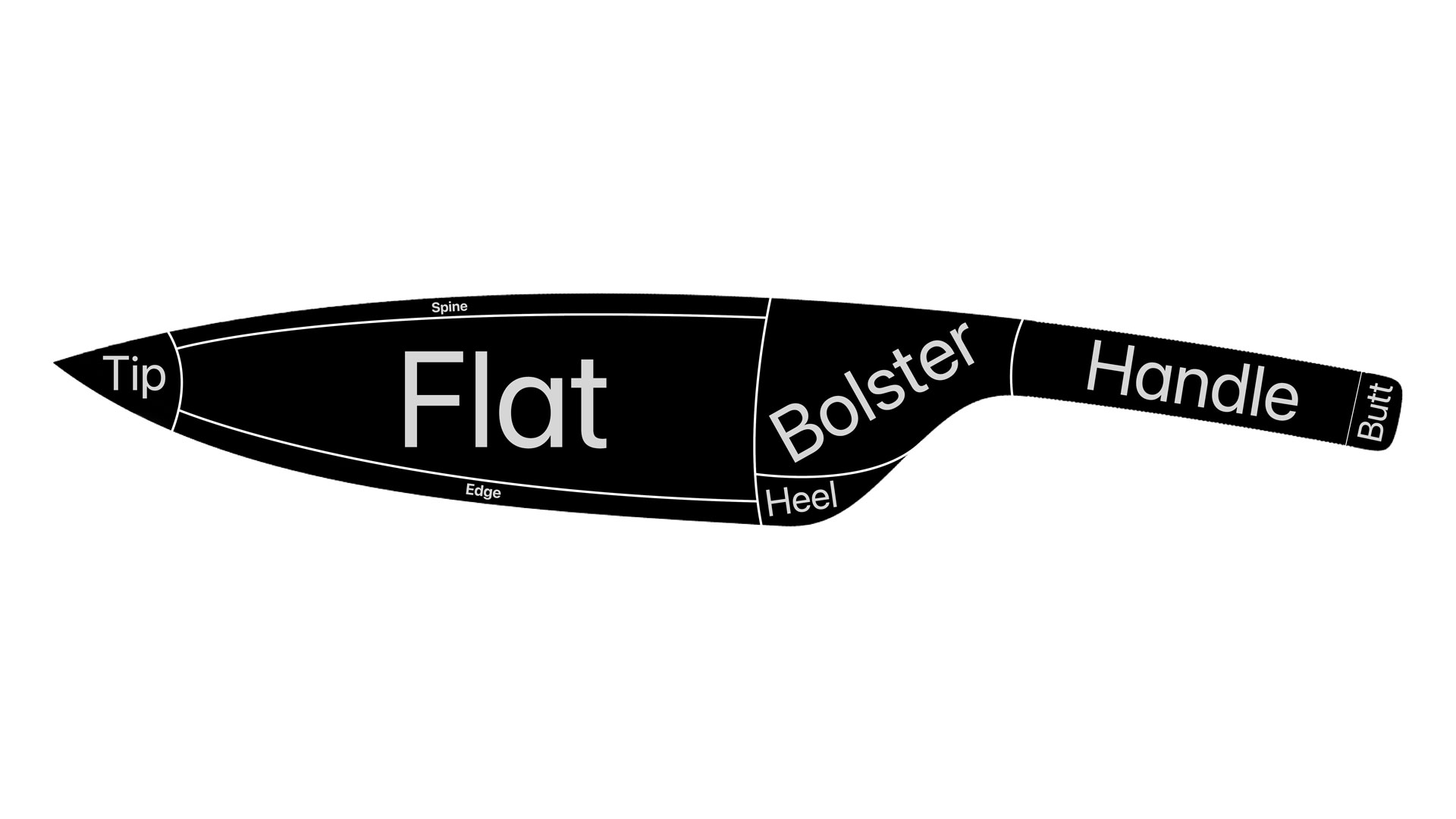

Anatomy of a Chef's knife

The next big leap in human society will be known as the ‘Space age’. Spaceships, rockets and astronomy are becoming increasingly prominent. People now prefer personal products to be long lasting and low maintenance. The correct method for chopping is by utilising a pinch grip. This product should encourage this technique.

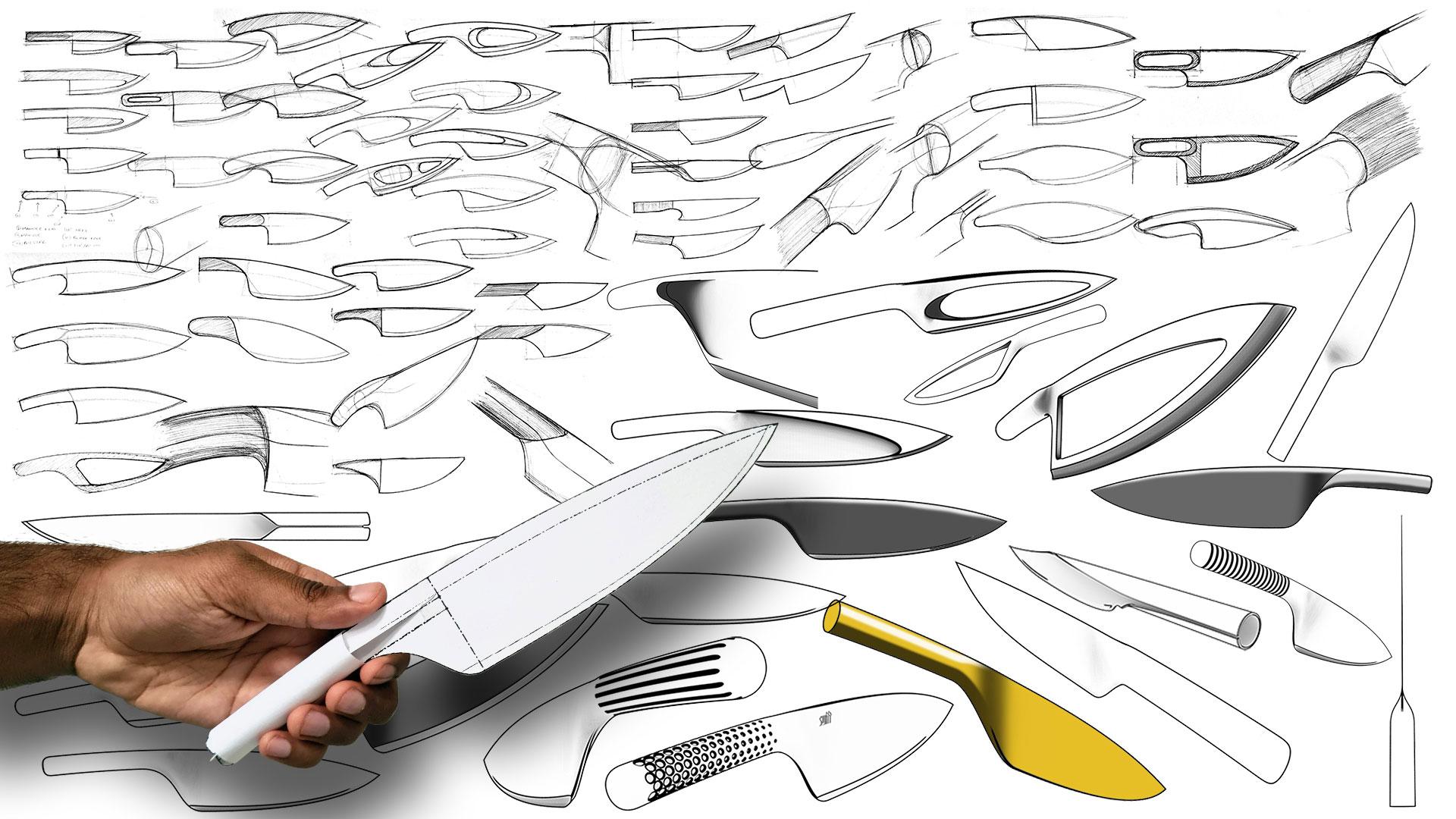

Thumbnail sketches and card mockups allowed proportions to be carefully refined.

Rendering out different CMF options allowed immediate analysis of what options work well for the product. The final decision was based on creating a knife that was inspired by space. The benefits of the material used is truly astonishing...

Have a play with the 3D model here!

Introducing ‘Swift’, a kitchen knife made from GRX-810. This new material, created by NASA, is made from equal amounts of Nickel-Cobalt-Chrome, powder coated in nano-scale Yttria (Yttrium oxide) via cusic mixing.

Since additive manufacturing is the method used for NASA’s GRX-810 alloy, a knurled grip can be added during manufacturing rather than as a post process. This grip ensures the handle is anti-slip.

The handle seamlessly blends into the flat of the blade. By designing a bolster that implements G3 curvature continuity, it allows an array of different hand shapes and sizes. This encourages people to optimally cut their food using a pinch grip.

GRX-810 is an ODS alloy created by NASA. This material has 2x the strength to resist fracturing over other state of the art super-alloys. Furthermore, it has 3.5x more flexibility to stretch/bend prior to fracturing.

The ‘Swift’ set includes various knifes for an array of cutting jobs. The handle remains the same for all the knives, but the main blade flat differs depending on the knife type. The bolster also varies depending on the blade type dimensions.

Swift will stay sharp for 20x longer than an average steel knife. Say goodbye to sharpening, and hello to Swift.

'One small step for [a] man, one giant leap for mankind'. Upon NASA recently creating the breakthrough GRX-810 material, Neil Armstrong's quote is poignant now more than ever. This new material was originally researched to be used for rockets and spacecraft to withstand harsh environments. The unprecedented strength properties make it perfect to translate to a domestic setting. Furthermore, the creation of this alloy powder is not too costly, and the ability to utilise additive manufacturing ensures cost is not a huge factor.

GRX-810 is made from a fusion of Nickel, Cobalt and Chromium. This is then mixed with an oxide (in this case, Yttria). This finish prevents corrosion can also be used to colour the material (i.e. black as above).

Acknowledgements: Castleton, C. Ramzan, H

Date: September 2022